Introduction to Sausage Packaging

In the competitive world of sausage production, ensuring product quality and longevity is paramount to maintaining customer satisfaction and brand reputation. Oxygen exposure, while often overlooked, is a silent threat that can lead to rapid spoilage, off-flavors, and unappealing discoloration. The good news is that modern sausage packaging solutions, such as vacuum sealing, modified atmosphere packaging (MAP), and advanced thermoforming, provide reliable ways to combat oxidation and extend shelf life. By investing in airtight and sustainable packaging, manufacturers can protect their products while meeting growing consumer demands for both freshness and eco-friendliness.

To stay ahead in the industry, it’s vital for technical buyers and food manufacturers to adopt packaging technologies that not only prevent spoilage but also streamline production processes. From leveraging smart packaging with oxygen scavengers to exploring new, sustainable materials, there are numerous opportunities to optimize your packaging strategy.

If you’re ready to take your sausage packaging to the next level, explore Velec Systems’ range of innovative solutions designed to preserve product quality while enhancing efficiency. Contact our team today to discuss how our specialized equipment can help you safeguard your products against the effects of oxygen exposure and keep your customers coming back for more. Let’s work together to ensure your sausages stay as fresh and flavorful as the day they were made.

Quick Takeaways

- Oxygen exposure accelerates oxidation in sausages, leading to rancidity, off-flavors, and discoloration.

- Airtight packaging solutions such as vacuum sealing and MAP are essential to protect sausages from oxidation and extend their shelf life.

- Lipid and protein oxidation in sausages results in texture and flavor degradation.

- Innovative packaging technologies like thermoforming and flow wrap provide efficient sealing options that minimize oxygen exposure.

- Sustainable packaging materials can offer airtight protection while reducing environmental impact.

- Smart packaging solutions, including oxygen scavengers, help monitor and control the storage environment to maintain sausage freshness.

- Investing in the right sausage packaging strategy can significantly improve product quality, reduce waste, and satisfy consumer expectations.

Introduction to Sausage Packaging and Oxygen Exposure

Why Proper Packaging Matters in the Food Industry

Effective packaging serves as the first line of defense against environmental factors that can compromise food quality. For sausages, packaging not only contains the product but also protects it from oxygen, moisture, and contaminants. The right packaging solution can significantly extend shelf life, preserve flavor, and maintain the visual appeal that consumers expect.

Understanding Oxidation: How Oxygen Affects Sausages

Oxygen exposure initiates oxidation processes in meat products, leading to several undesirable effects:

- Chemical Reactions Between Oxygen and Meat: Oxygen reacts with lipids and proteins in sausages, causing lipid oxidation and protein degradation. These reactions result in rancidity, off-flavors, and textural changes that negatively impact product quality.

- Impact on Flavor, Color, and Shelf Life: Oxidation leads to the development of unpleasant flavors and odors, discoloration (such as greying or browning), and a reduction in shelf life. Consumers are likely to reject products exhibiting these signs, leading to potential economic losses.

By implementing airtight packaging solutions, manufacturers can mitigate the adverse effects of oxygen exposure, ensuring that sausage products remain fresh, flavorful, and visually appealing throughout their intended shelf life.

The Science Behind Meat Oxidation

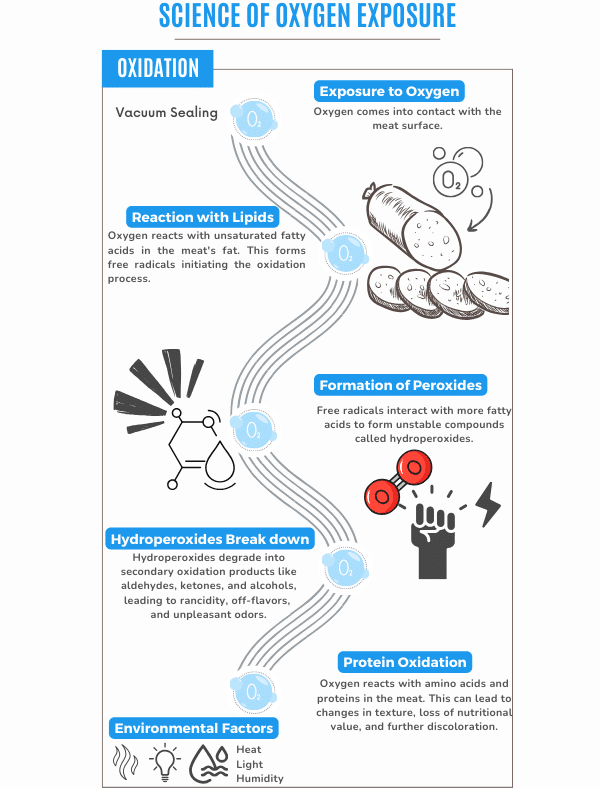

What Is Oxidation and How Does It Occur?

Oxidation in meat occurs when oxygen molecules interact with unsaturated fatty acids, initiating lipid oxidation. This process produces free radicals, which further propagate oxidation, leading to rancidity and off-flavors. Protein oxidation involves the modification of amino acids, affecting the meat’s texture and nutritional value.

Factors That Accelerate Oxidation in Sausages

Several factors can accelerate oxidation in sausages:

- Temperature, Light, and Humidity: Elevated temperatures, exposure to light, and high humidity levels can increase the rate of oxidation. For instance, storing sausages under fluorescent lighting can lead to significant color changes and flavor deterioration.

- Impact of Packaging Materials on Oxidation Rates: The choice of packaging material plays a crucial role in controlling oxidation. Materials with high oxygen permeability allow more oxygen to penetrate, accelerating oxidation. Conversely, materials with low oxygen transmission rates (OTR) provide better protection against oxidation.

Understanding these factors enables manufacturers to implement strategies that minimize oxidation, such as selecting appropriate packaging materials and controlling storage conditions.

Why Sausage Packaging Needs an Airtight Solution

The Role of Packaging in Preserving Product Quality

Packaging serves multiple functions, including protection from environmental factors, containment, and communication. In the context of sausages, packaging must effectively shield the product from oxygen to prevent spoilage and maintain quality.

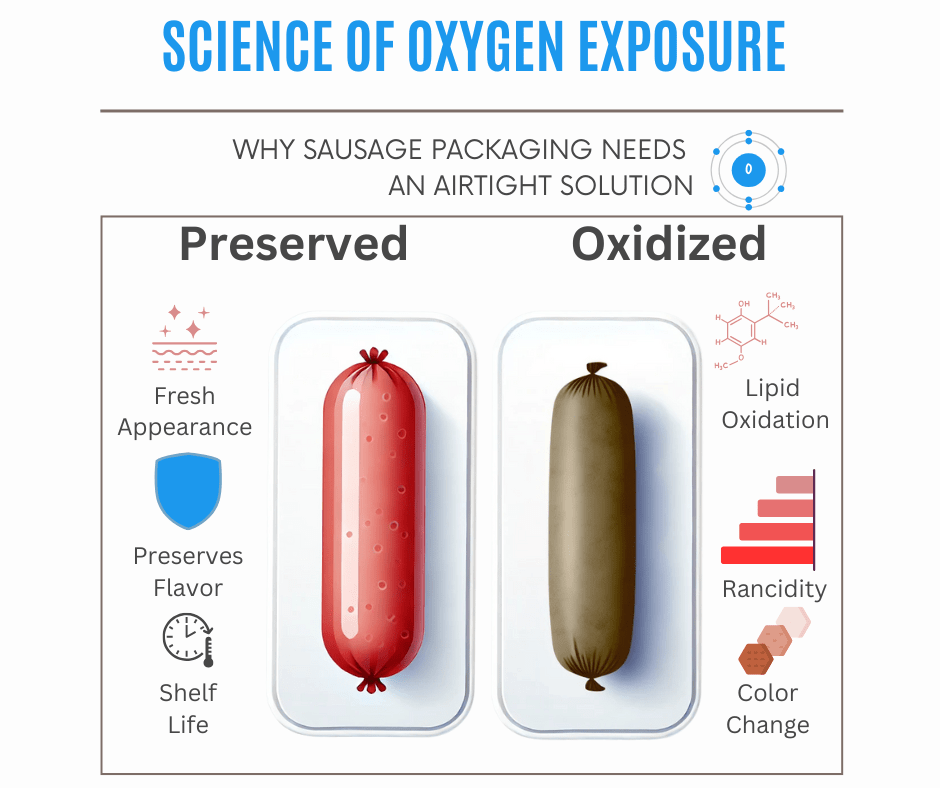

Consequences of Oxygen Exposure on Sausage Products

Exposure to oxygen can lead to:

- Spoilage and Microbial Growth: Oxygen supports the growth of aerobic spoilage microorganisms, leading to spoilage and potential food safety concerns.

- Color Changes and Loss of Fresh Appearance: Oxidation causes discoloration, such as greying or browning, making the product less appealing to consumers.

Implementing airtight packaging solutions helps mitigate these issues, ensuring that sausage products remain safe, appealing, and of high quality throughout their shelf life.

Types of Sausage Packaging to Prevent Oxidation

Vacuum Packaging

Vacuum packaging involves removing air from the package before sealing, creating a low-oxygen environment that inhibits oxidation and microbial growth.

- How Vacuum Sealing Extends Shelf Life: By eliminating oxygen, vacuum packaging slows down oxidative reactions and microbial activity, thereby extending the product’s shelf life.

- Best Practices for Vacuum Sealing Sausages: Ensuring a complete seal and using packaging materials with low oxygen permeability are crucial for the effectiveness of vacuum packaging.

Modified Atmosphere Packaging (MAP)

MAP replaces the air inside the package with a specific gas mixture, often comprising nitrogen and carbon dioxide, to inhibit oxidation and microbial growth.

- Benefits of MAP for Sausage Preservation: MAP can significantly extend shelf life by creating an environment that slows down spoilage processes.

- Common Gases Used in MAP Systems: Nitrogen is used to displace oxygen, while carbon dioxide inhibits microbial growth.

Other Airtight Packaging Technologies

Innovations in packaging technology offer additional methods to protect sausages from oxidation.

- Flow Wrap Packaging and Its Advantages: Flow wrap packaging provides a tight seal around the product, reducing oxygen exposure and maintaining freshness.

- Thermoforming Machines for Efficient Sealing: Thermoforming machines create custom-fitted packaging that minimizes air pockets, enhancing the protective barrier against oxygen.

Selecting the appropriate packaging method depends on factors such as product type, desired shelf life, and production scale.

Innovative Packaging Materials and Technologies

The Rise of Sustainable Airtight Packaging

Sustainability is becoming increasingly important in packaging decisions.

- Biodegradable Films and Eco-friendly Options: Biodegradable films made from renewable resources provide airtight protection while reducing environmental impact.

- Balancing Sustainability with Functionality: It’s essential to ensure that sustainable packaging materials still offer the necessary barrier properties to protect the sausage product from oxygen exposure.

Smart Packaging Solutions for Sausage Preservation

Smart packaging solutions like oxygen scavengers and sensors help monitor and control the storage environment, ensuring optimal freshness throughout the supply chain.

- Oxygen Scavengers and Indicators: These are small inserts placed inside the packaging that actively absorb oxygen, reducing any remaining oxygen within the package and preventing oxidation.

Conclusion

In the competitive world of sausage production, ensuring product quality and longevity is crucial to maintaining customer satisfaction and brand reputation. Oxygen exposure is a silent threat that can lead to rapid spoilage, off-flavors, and unappealing discoloration. However, with modern sausage packaging solutions, such as vacuum sealing, modified atmosphere packaging (MAP), and advanced thermoforming, manufacturers can effectively combat oxidation and extend shelf life.

By investing in airtight and sustainable packaging, manufacturers can protect their products, meet consumer demands for freshness, and enhance efficiency across production lines. If you’re ready to optimize your packaging and safeguard your sausage products from the effects of oxygen exposure, explore the innovative solutions offered by Velec Systems today.

FAQs

1. How does oxygen exposure affect sausage quality?

Oxygen exposure accelerates oxidation in sausages, leading to rancidity, off-flavors, and discoloration. Using airtight sausage packaging, such as vacuum sealing or modified atmosphere packaging (MAP), helps prevent these negative effects and maintains product freshness.

2. What are the best packaging methods to reduce oxidation in sausages?

The most effective methods include vacuum packaging and MAP. Vacuum sealing removes air from the package, reducing oxygen levels to nearly zero, while MAP replaces air with a specific gas mixture, like nitrogen and carbon dioxide, to prevent spoilage. Both techniques help preserve the flavor, texture, and color of sausages, extending their shelf life.

3. Can sustainable packaging materials still provide an airtight seal?

Yes, there are eco-friendly options like biodegradable films that offer airtight protection while reducing environmental impact. These materials are designed to provide the necessary barrier properties to prevent oxygen exposure, ensuring your sausages remain fresh without compromising on sustainability.

4. What is the role of oxygen scavengers in sausage packaging?

Oxygen scavengers are small packets or inserts that actively absorb residual oxygen inside sealed packages. By reducing oxygen levels further, they help prevent oxidation and spoilage, especially in cases where vacuum sealing or MAP might not eliminate all oxygen.

5. Why is modified atmosphere packaging (MAP) ideal for sausage products?

MAP is ideal because it replaces the oxygen inside the package with inert gases like nitrogen or carbon dioxide, slowing down microbial growth and oxidation. This method is highly effective in extending the shelf life of sausages, making it a preferred choice for food manufacturers looking to maintain product quality over time.

References

Velec Systems. (2024). Sausage Packaging: The Ultimate Guide

Velec Systems. (2024). The Art of Sausage Packaging Design

Velec Systems. (2024). Optimizing Sausage Packaging: Centrifugal Machines & TCO

Velec Systems. (2024). Sausage Packaging for Temperature Regulation

Velec Systems. (2024). Custom Sausage Packaging: Meeting the Needs of Niche Markets