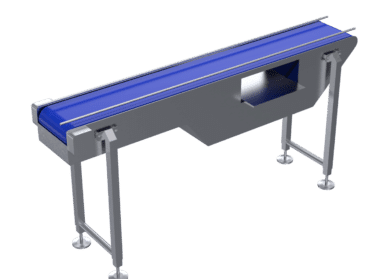

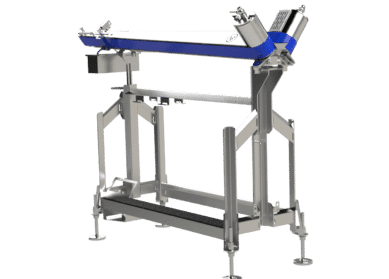

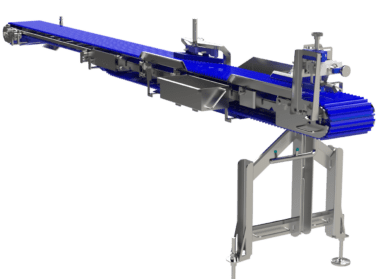

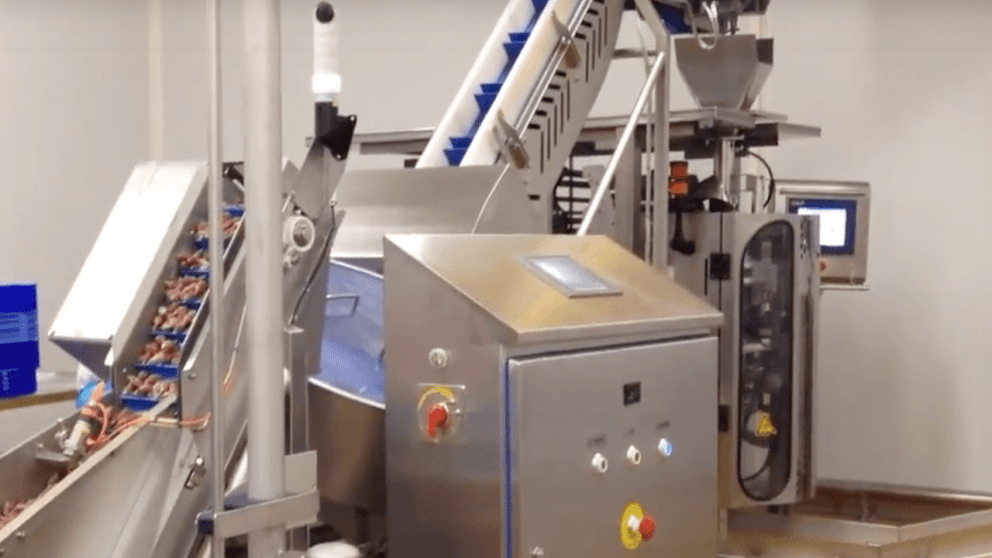

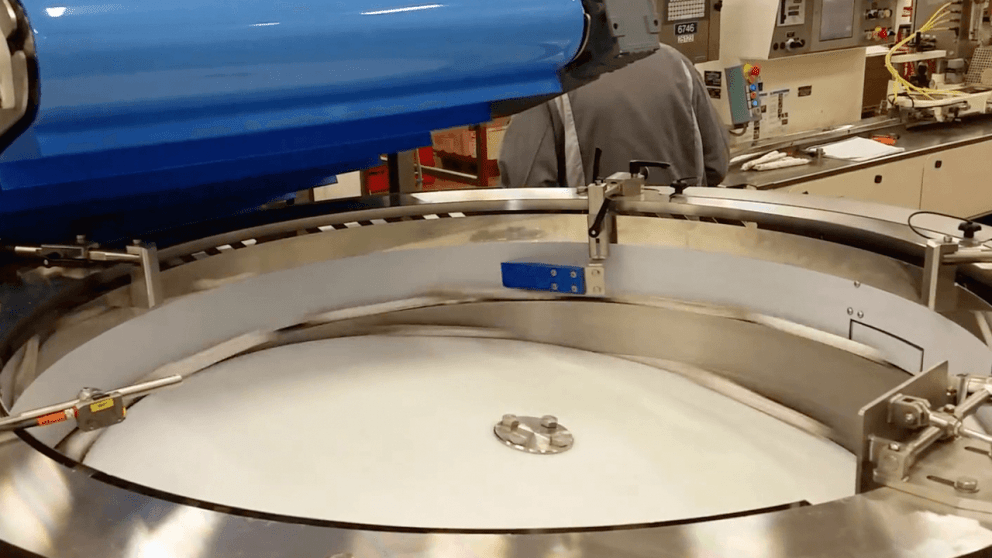

Conveyors

Conveyors are crucial to your production efficiency and product quality.

To help you reduce machine downtime, optimize your cleaning operations and maintain the optimal quality of your products, our experts develop tailor-made elevator conveyors (Unpicking, distribution, orientation, by-pass, transfer, batching, etc.), specific to your products and operating constraints, enabling you to optimize your process.

Because your lines are unique, each machine is designed according to your needs, so as to integrate perfectly with your production line.

For a complete, turnkey, hygienic solution, consult our specialized subsidiary, Acemia.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team. Our level of hygiene requirements exceeds the best standards of the food industry and exceeds the recommendations of the EHEDG (European Hygienic Engineering and Design Group).

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).