Loading your spring rolls into their packaging requires extreme care, hygiene, and efficiency! Our spring rolls loading solution has been designed to help you improve your OEE.

The Spring Rolls Loader is located after the freezing stage. These are fragile products with a crispy and greasy texture and an irregular shape. This fried product cannot withstand too many shocks, as it risks crumbling. Therefore, it is crucial to load them with the most hygienic equipment possible to prevent the development of bacteria before packaging.

Our team has thus focused all its expertise to offer you the most hygienic Spring Rolls Loader on the market. Designed according to EHEDG (European Hygienic Engineering And Design Group) standards, it meets and exceeds the recommendations of the food industry.

Since spring rolls manufacturers typically handle a wide range of recipes with different lengths, weights, and diameters, the VELEC Spring Rolls Loader is highly versatile.

Capable of loading all types of nems into your packaging solution in even or odd numbers, it offers great production flexibility.

Increase your OEE

| Diameter | from 40 to 50mm |

| Length | from 80 to 100mm |

| Output | Up to 200 units/min |

| Energy | 400V – 50/60Hz – 32kw |

| Air pressure | 6 bars – 50m3/h |

Gentle Handling to Maximize Profits

Our Spring Rolls Loading solution offers gentle and appropriate handling for this fragile product, allowing it to remain in its initial state.

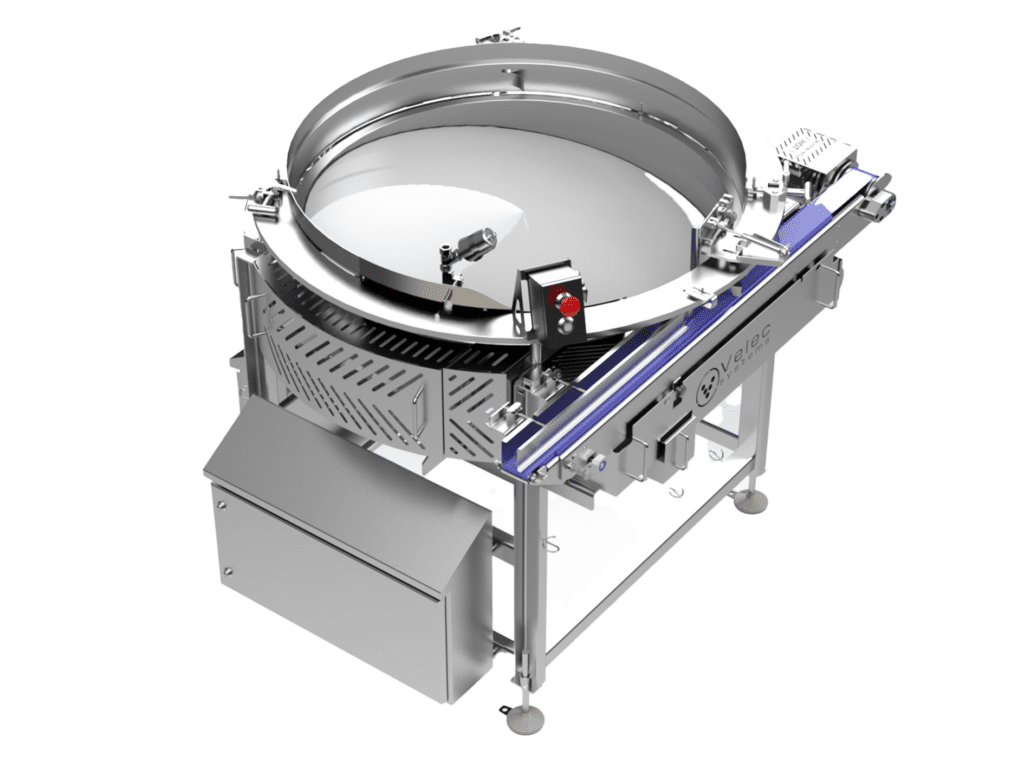

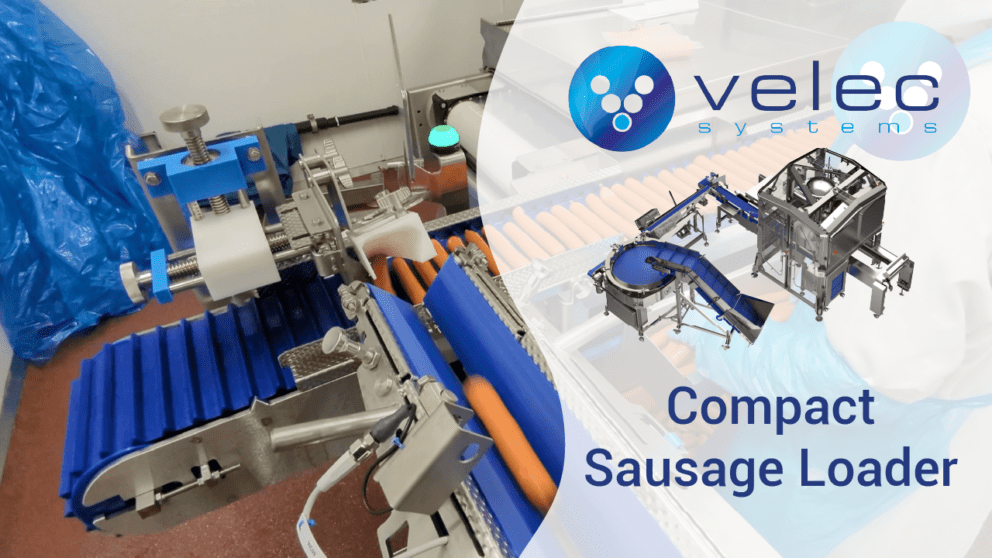

First, the spring rolls are handled on a conveyor elevator to be brought onto the centrifuge machine’s plate. It is thanks to this centrifugal force that the spring rolls gravitate to the edge of the plate to be transferred one by one to the edge of the drum. They are then guided one after another onto the exit conveyor, and then onto the piano belts.

The VELEC Spring Rolls Loader:

The Simplest & Safest on The Market

Your employees are your greatest asset. That’s why we’ve designed the easiest and safest spring rolls loader on the market.

For this reason, every element of the machine is at ground level, without stairs or platforms. Operations are minimized to the bare essentials for maximum safety and simplicity of operation for your employees.

Increase Your Productivity With The Help of Our Intuitive HMI

To assist you in operating and supervising your Spring Rolls Loader, an easy-to-use HMI (Human-Machine Interface) is at your disposal. Composed of intuitive screens, it is available in all languages upon request.

An ergonomic solution for minimal human-machine interaction.

The interface of the VELEC Spring Rolls Loader is as intuitive as your smartphone. It provides access to all kinds of information, including videos on disassembly and line cleaning.

Take Advantage of Remote Assistance to Maximize Your Machine Uptime

Interactive assistance is made possible through integrated remote access via Ethernet, Wi-Fi, or SIM card. The 360° camera control option enables you to establish a direct connection with our experts who will guide you in restoring your line. This way, you save on the travel expenses of our teams.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).