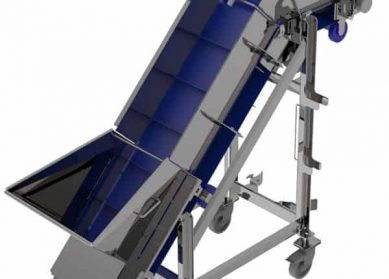

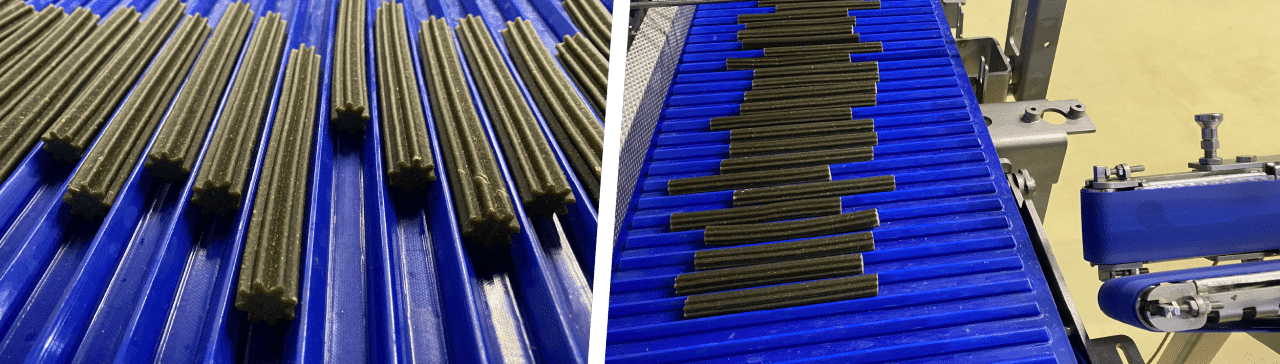

Loading your chew sticks into their primary packaging requires gentle and hygienic handling while being as efficient as possible. Our chew stick loading solution is designed to help you improve your OEE!

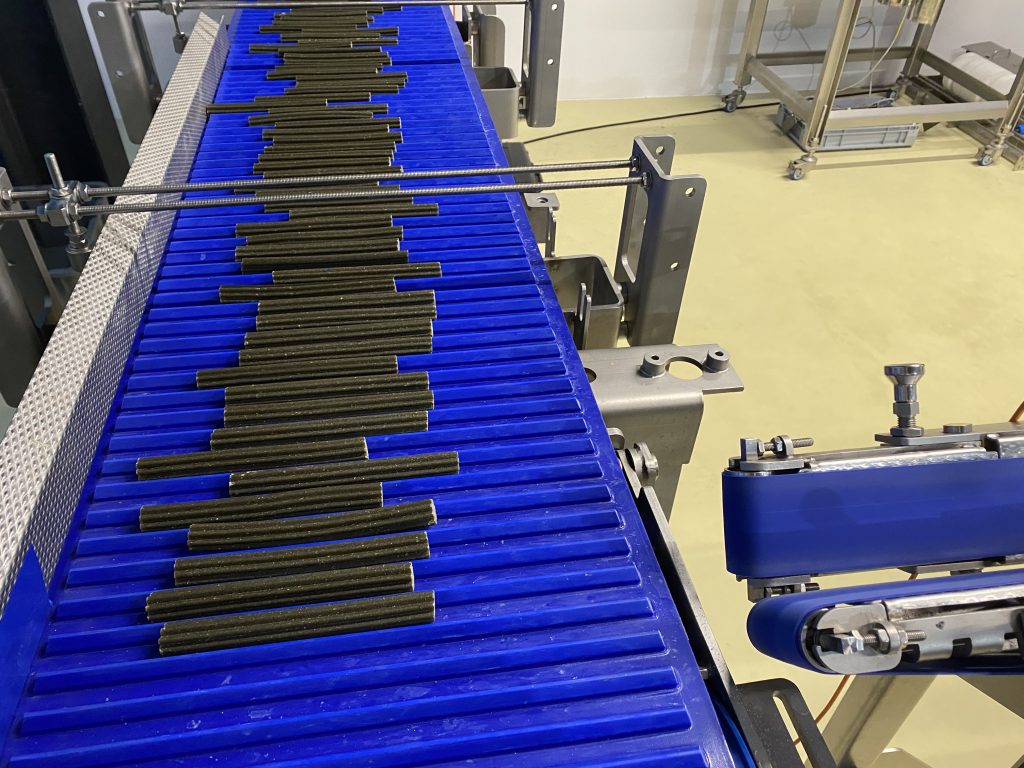

If you’re in the business of producing and packaging pet sticks, you know how tedious and time-consuming it can be to manually count and load them into their primary packaging. Not only is this process labor-intensive, but it can also result in inconsistencies and errors that can affect the quality of your product.

Fortunately, our solution can help alleviate these issues. Our state-of-the-art machine is designed to accurately count and load pet sticks into their primary packaging with precision and speed. With advanced technology, you can trust that each and every pet stick is counted and loaded correctly, resulting in a consistent and high-quality product.

You, as a pet food manufacturer, usually process a wide range of recipes with different casings, lengths, weights and diameters.

Compatible with many packaging systems, the pet stick loader will help you gain productivity.

In addition to improving the consistency and quality of your product, our machine can also help to increase productivity and efficiency in your production process. By eliminating the need for manual counting and loading, your employees can focus on other important tasks, ultimately improving your bottom line.

Benefit from a Custom-made Solution Designed to Adapt to Your Production Requirements

Our experts gathered all their know-how to design the most flexible and versatile solution, capable of adapting to your products and your conditioning process. Our solution is also designed with your company’s unique needs in mind. We offer customization options to ensure that the machine is tailored to fit seamlessly into your production line, no matter the size or scope of your operation.

The Velec pet sticks loader packs your sticks quickly thanks to predefined recipes. It adapts to all products, loads in all directions (parallel and perpendicular) and in all packaging configurations (single or multilayer, even or odd numbers).

Maximize your Production Process with a Gentle Equipment

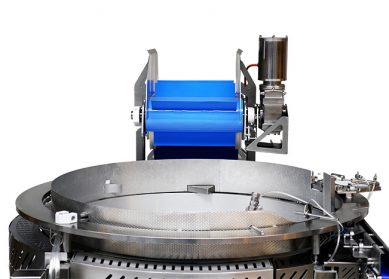

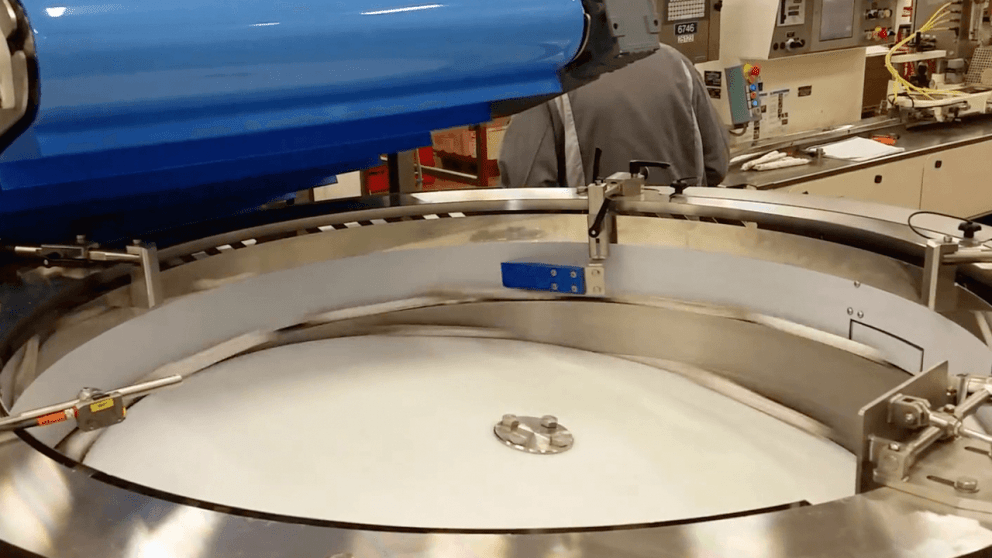

To avoid any damage or breakage of your products, we use the centrifugal force to bring them towards the edge of the tray. From there, they are carefully loaded one after the other onto the conveyor. With no mechanical constraints, your products remain in perfect condition.

To go further, a quality control system rejects non-compliant products according to their shape, diameter and length.

Our user-friendly HMI provides you with statistics on your most recurring manufacturing defects. It allows you to adjust your quality plans and optimize your production. Available in all languages on demand, our HMI helps you pilot, monitor, and supervise your pet sticks’ loader.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team. The stick loader is located after the drying stage, and upstream of your main packaging system. It is therefore essential that this area is as hygienic as possible to prevent the development of bacteria before packaging your chew sticks. The VELEC petfood loader is placed right after your drying unit and before your conditioning system. Able to load up to 2,240 products/min and custom-made to answer your needs, it helps you optimize your productivity thanks to its high-end features.

Our team has thus concentrated all its know-how to offer you the most hygienic stick loader on the market. Indeed, it meets and exceeds the recommendations of the pet food industry. It has been designed according to the EHEDG (European Hygienic Engineering And Design Group) standards.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).

Chew Sticks Loader

Chew Sticks Loader