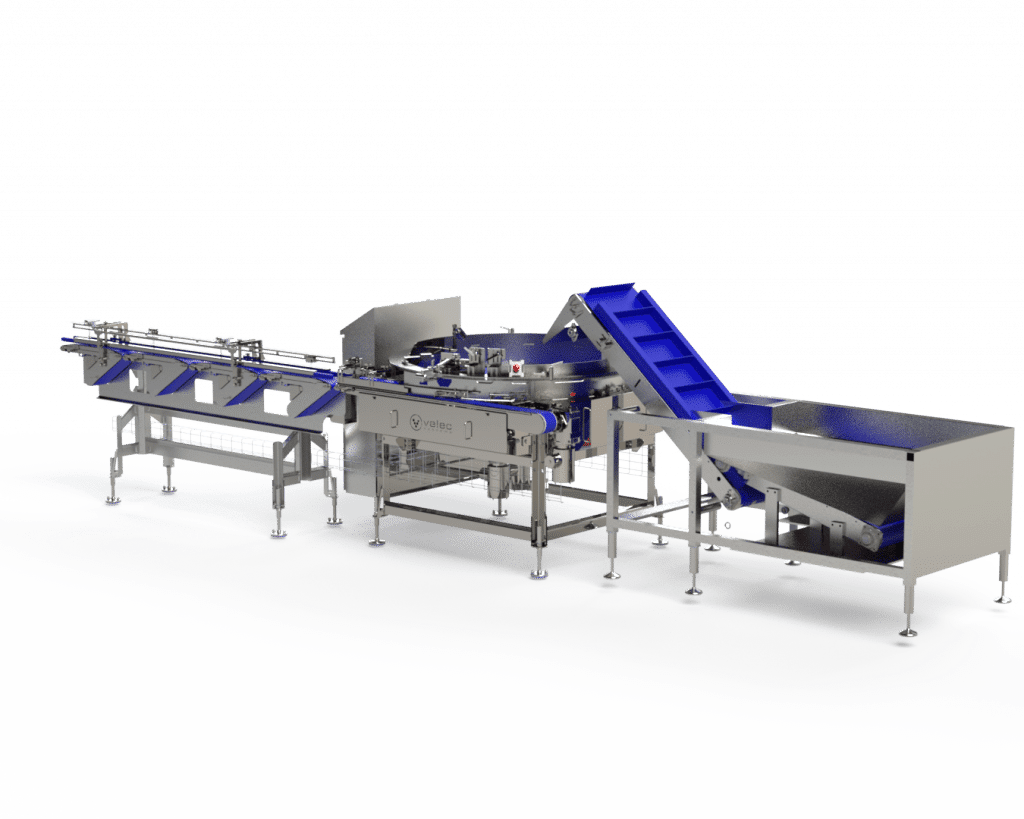

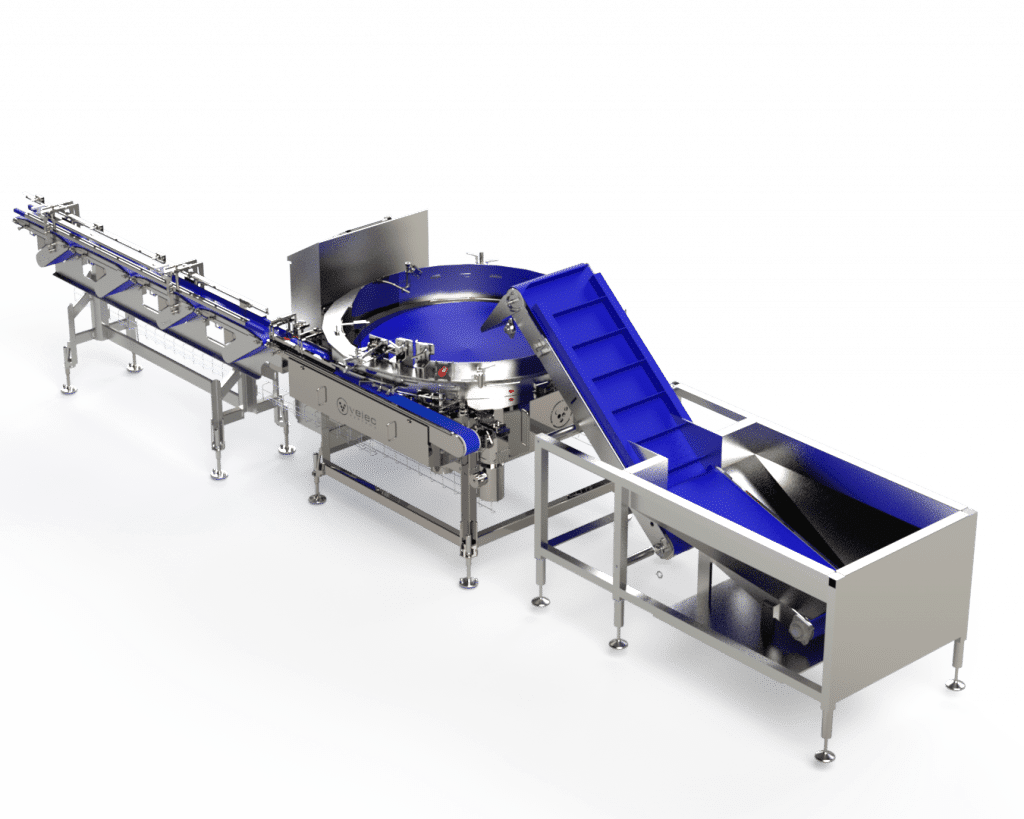

Placed downstream of your drying unit, the VELEC dry sausage bagger gently loads your products into their primary packaging.

Highly hygienic, our solution handle your products delicately to help you improve your OEE!

Whatever the shape, diameter or length of your sausages, VELEC Systems has developed technical solutions adapted to each type of packaging:

- Counting and bagging

- Counting and canning

- Loading of thermoforming machine

Maximize Your Production Process by Minimizing your Losses

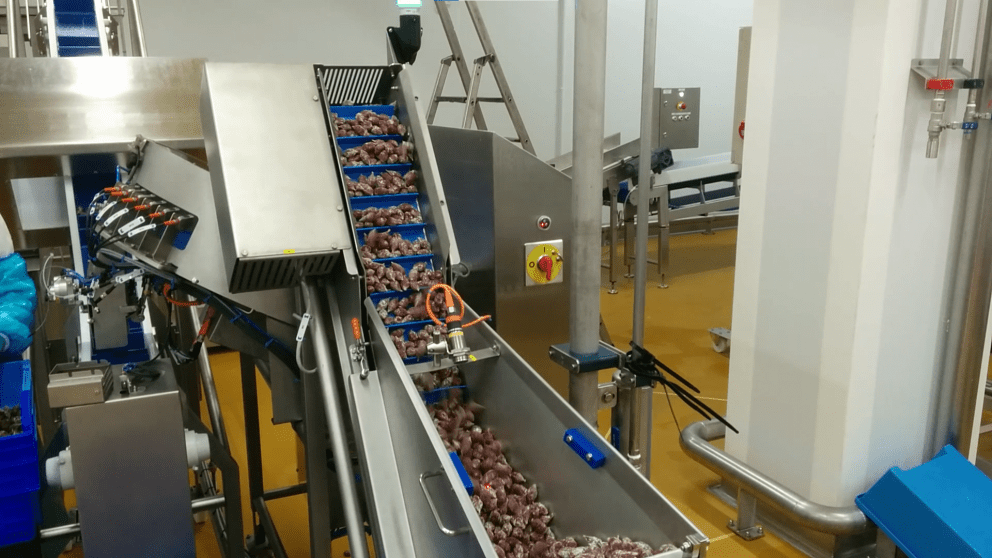

Fragile, wet or dry products are no longer a problem! At VELEC we developed a solution able to handle your products with care.

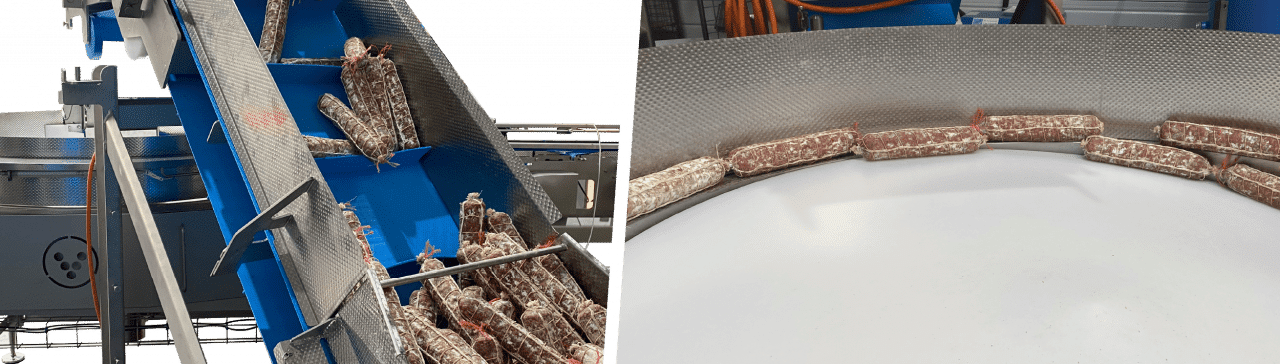

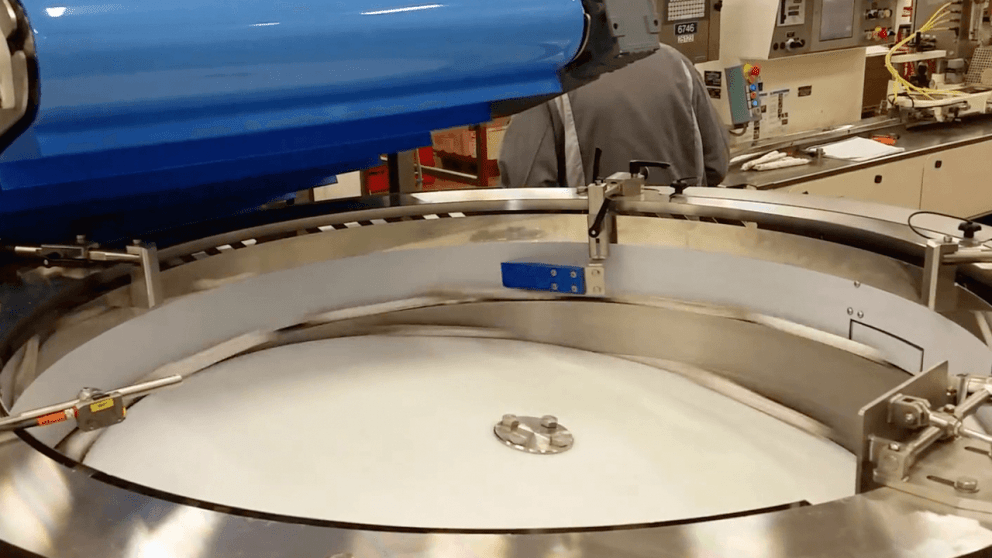

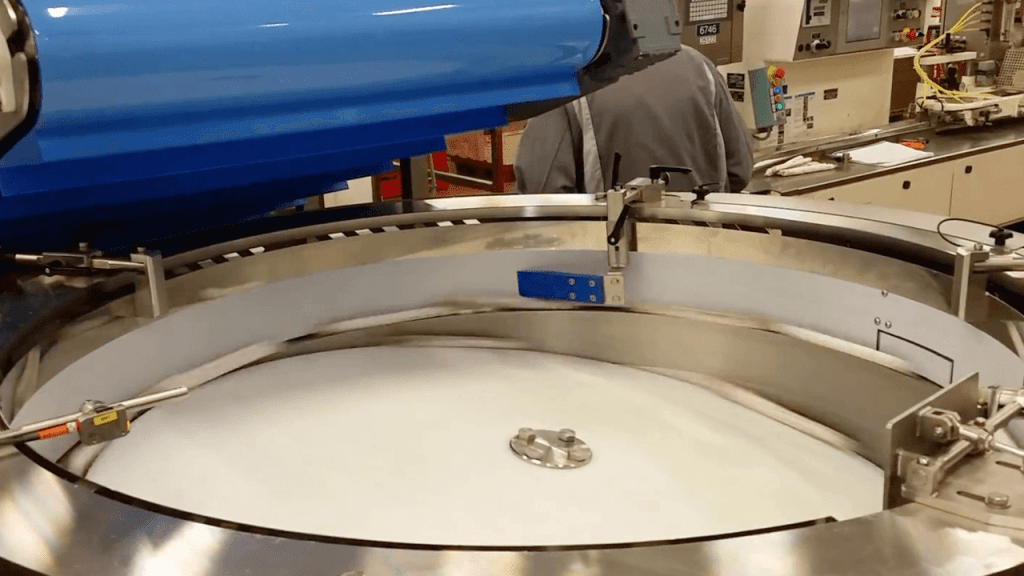

First, your dry sausages are handled on a smooth hygienic belt. The products are then transferred to the centrifugal machine plate, where the centrifugal force causes the sausages to gravitate to the periphery of the plate and to the edge of the drum. They are then led one by one onto the exit conveyor and onto the piano belts. Finally, the hygienically designed Pick-and-Place robot gently selects and places your dry sausages into their primary packaging.

The Most Versatile Loading Equipment for Every Packing Configuration

Because sausages manufacturers deal with a large range of sausages with various recipes, diameter, length, weight and casing, we developed a flexible and versatile solution.

The VELEC dry sausages bagger can load all types of dry sausages, with or without casing (including cellulose casing) and in all directions, parallel or perpendicular to the film movement (odd or even numbers).

Benefit from a Secured and Easy-of-use Solution

Employees are the most important asset of any organization. Therefore, we have designed the VELEC sausage machine to make their life easy and secured. For that reason, every single element of the machine is on the floor level without any stairs or platform, and operations are reduced to the very strict minimum.

Increase Productivity With The Help Of Our User-friendly HMI

To help you pilot, monitor and supervise your loader, a simple HMI composed of a series of intuitive screens is there to assist you. It is available in any language on simple demand, to better accommodate you.

An ergonomic solution for minimal human-machine interaction.

The VELEC Sausage loader’s interface is as intuitive as your smartphone. It provides access to all types of information, including videos of disassembly and cleaning of the line.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).