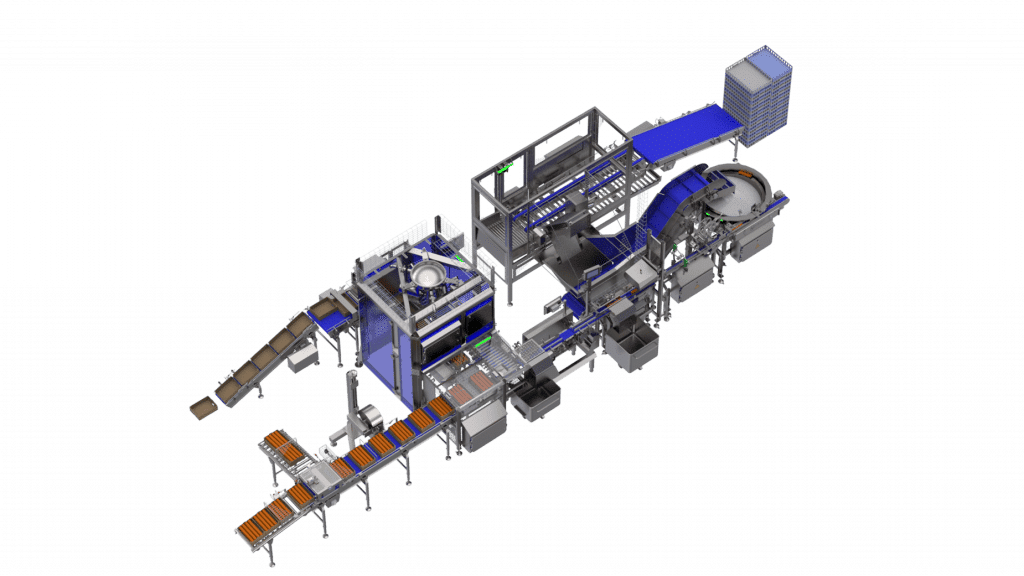

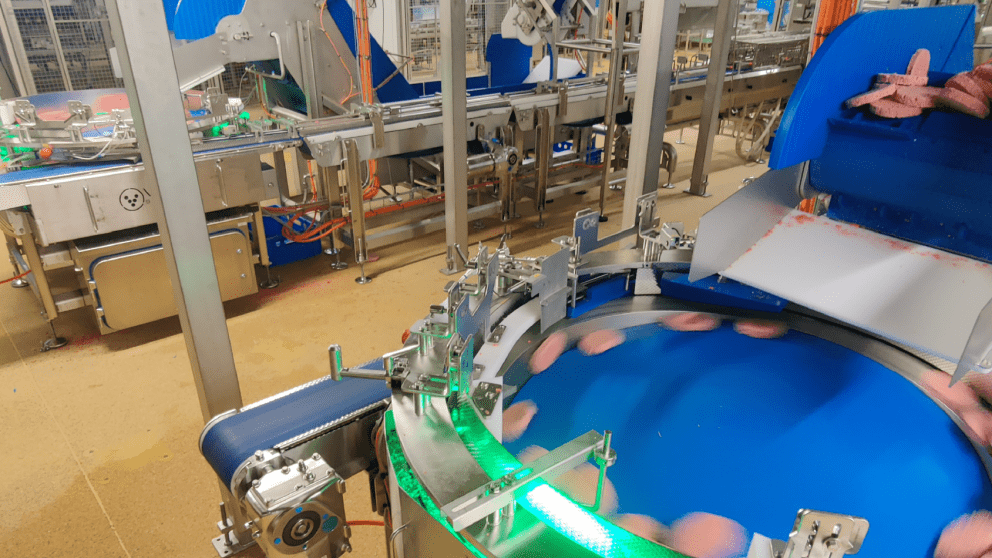

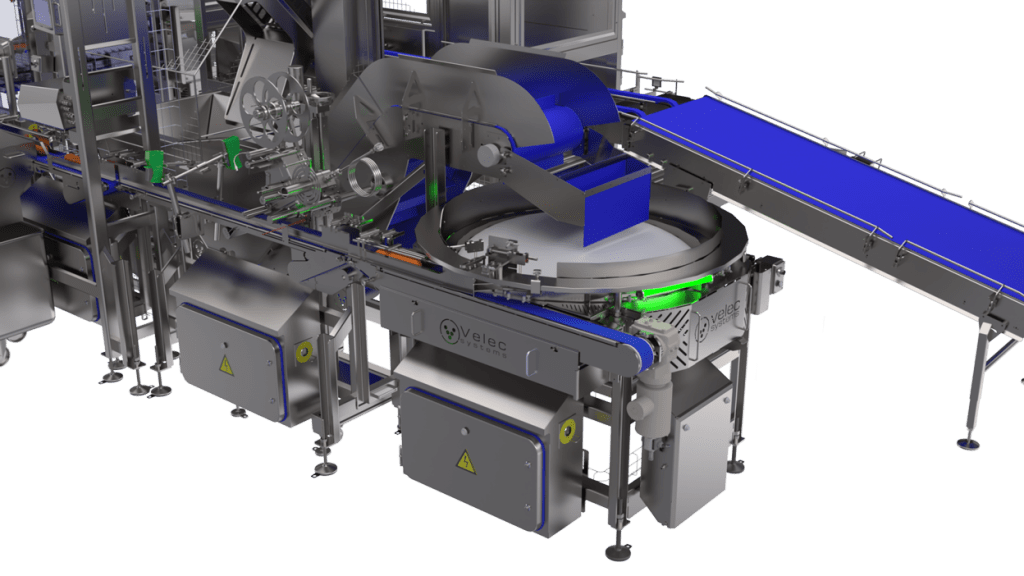

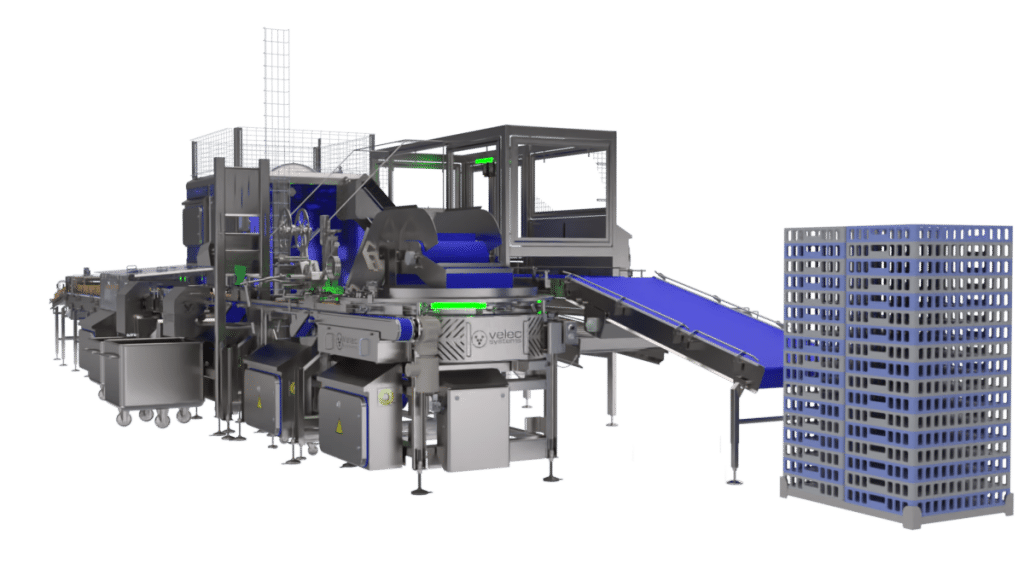

Discover our automated mechanical case packing solution for salami and mortadella, designed to optimize and speed up your packaging process. Our salami and bologna case packing solution orders and counts your products before placing them in their secondary packaging.

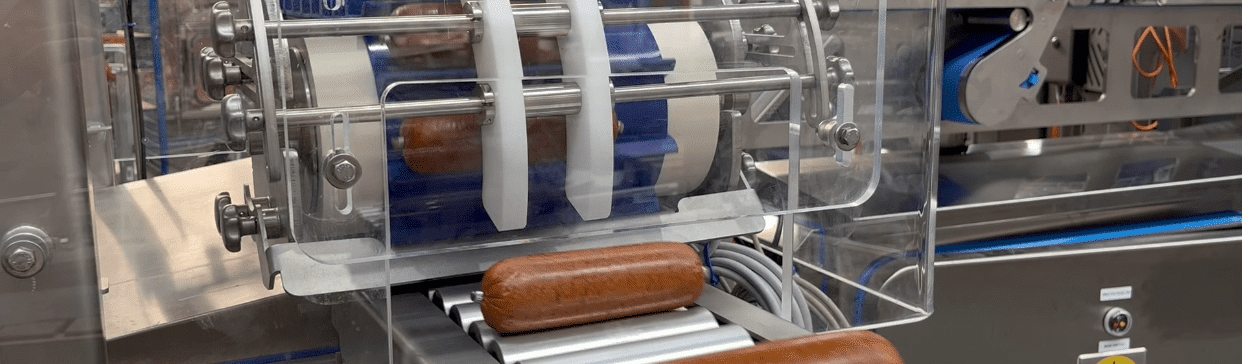

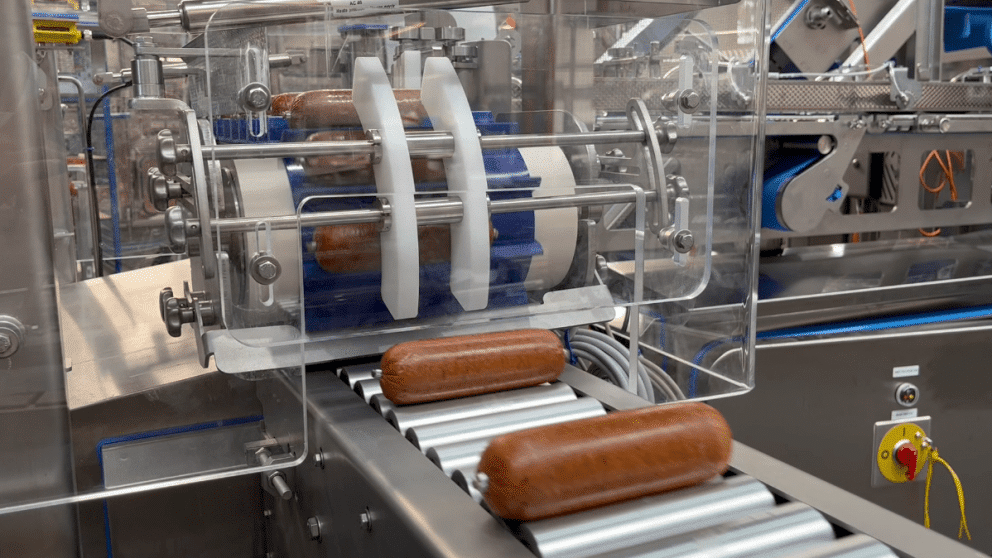

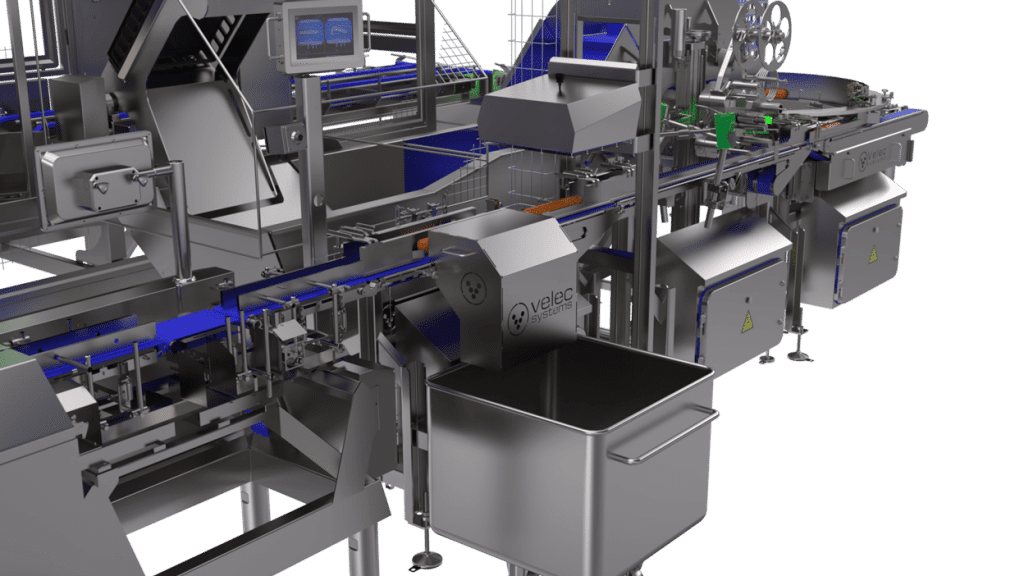

Our innovative system comprises a case turner, a centrifugal machine and a packaging robot, all working in harmony to offer you maximum efficiency and increased productivity.

Improve your efficiency, productivity and customer satisfaction with our tailor-made solution!

Capable of speeds up to 20,400 units/hour.

A Gentle Handling to Maximize your Profits

Our solution are optimized handle your products with extra care, causing them no damage. Your products remain in their original condition from the counting until they reach your customers.

You save time and ressources!

Improve Product Quality With our Optical Control

Improve product quality thanks to our optical control! Your products are automatically weighted and packed. Any defects or inconsistencies are identified and addressed in real-time to ensure you obtain perfect lots.

To help you further improve your quality plan, our HMI provides you with data on the most recurring defaults.

Optimize the Packing of Your Products

Our solution ensures that each boxe is packed with the optimized amount of products therefore reducing the risk of overpacking or underpacking which can lead to increased costs and waste.

Your products are packed faster and more efficiently than ever!

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).