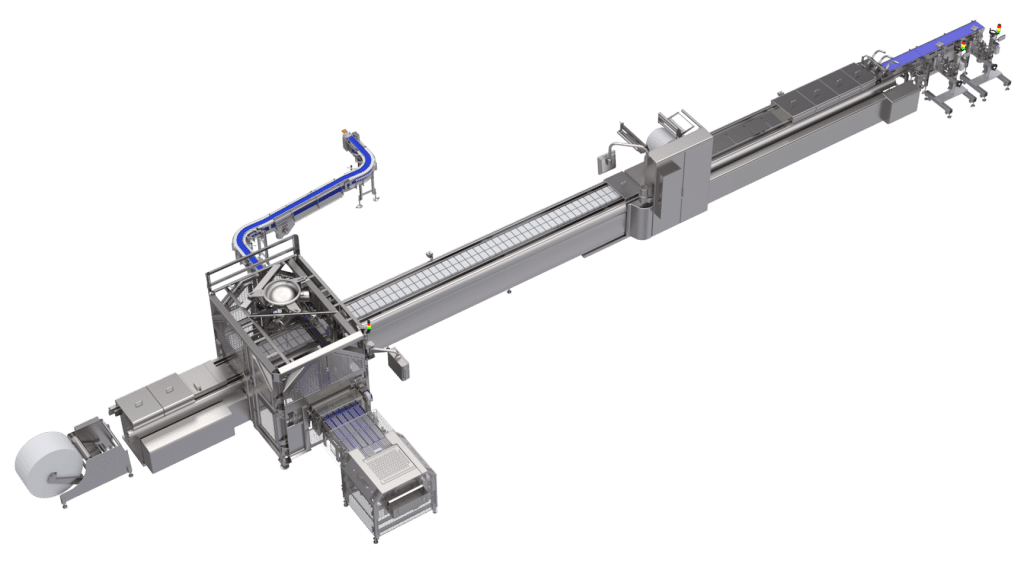

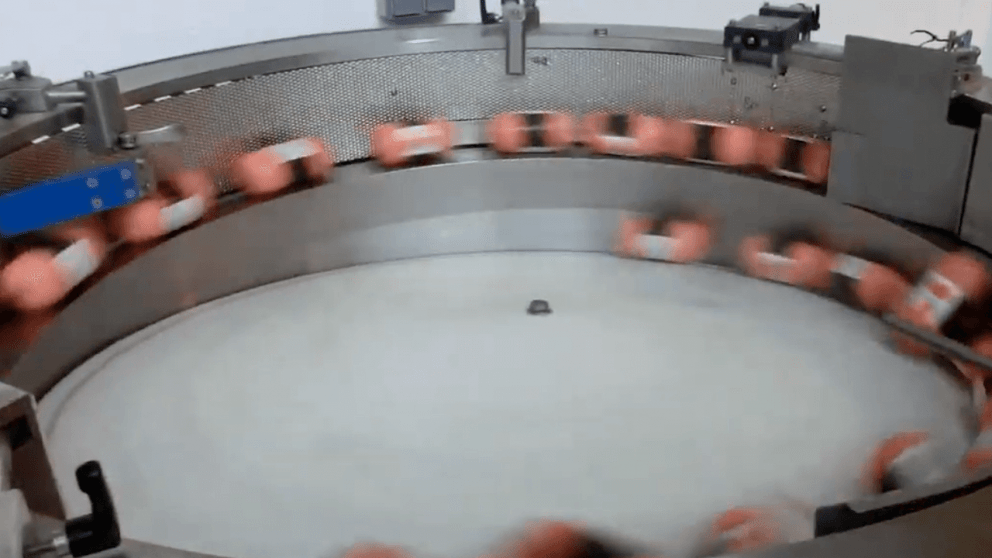

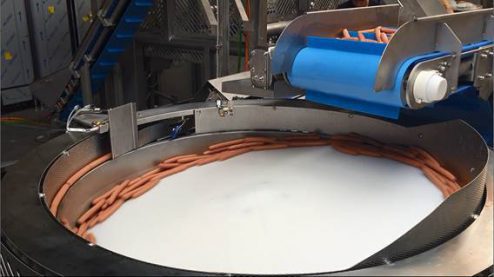

Our highly versatile sliced cheese loader adapts to your products weight and dimensions and loads them efficiently and precisely into your thermoformer.

It loads up to 7,200 products/hour.

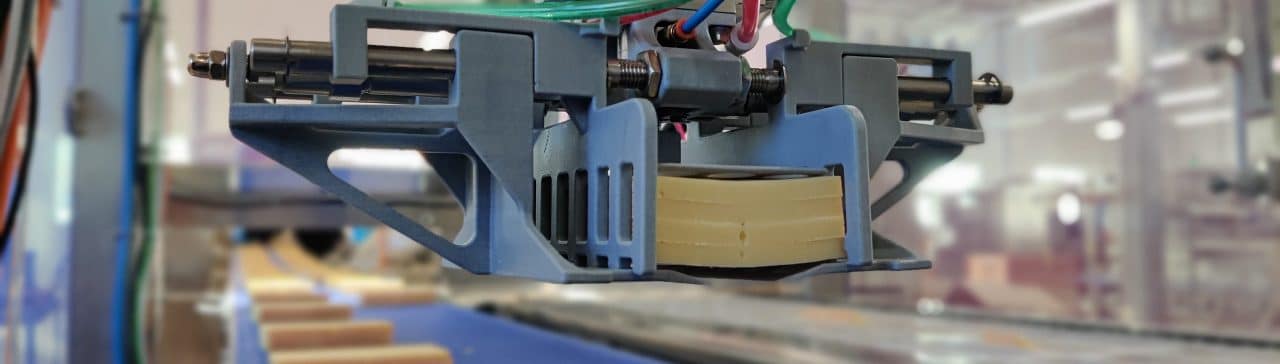

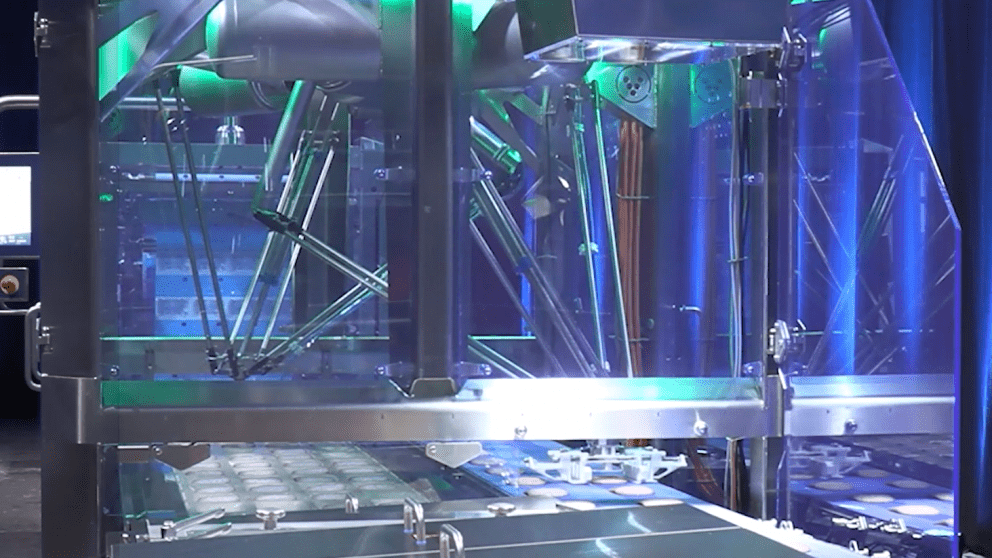

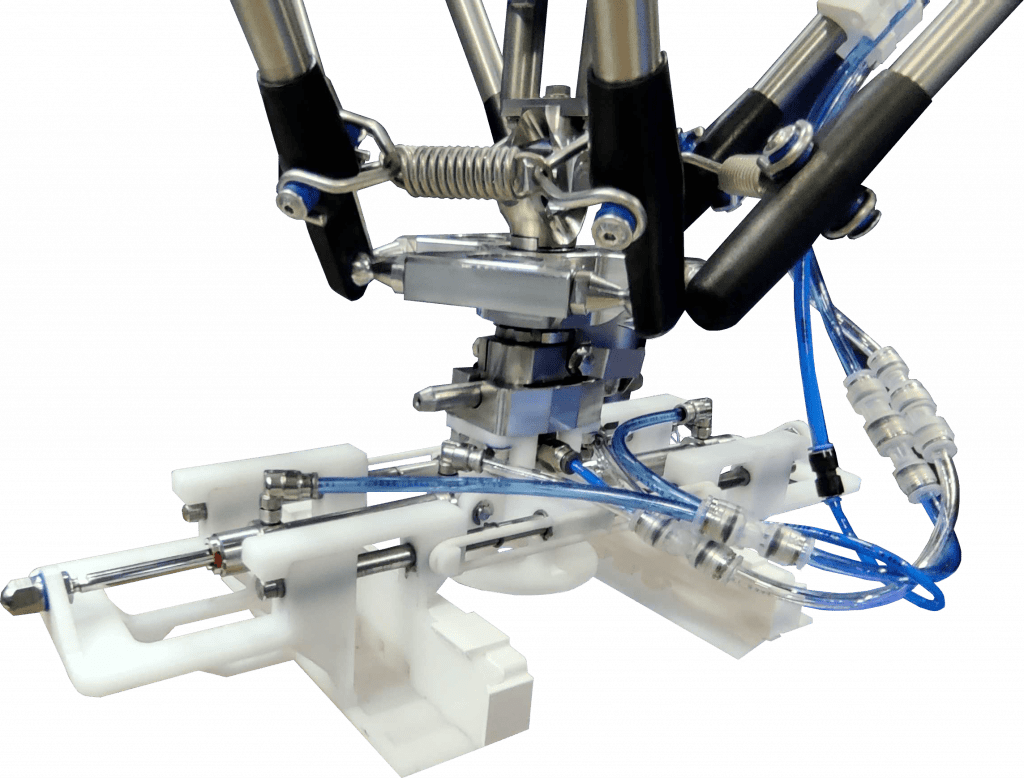

Optimize Your Process with Our Adaptive and Easy-to-Use Grippers

Designed by our experts, our grippers pick up your sliced products and place them in your thermoformed bags. To help you optimize your production, we offer various types of grippers for any applications:

- Vacuum (Venturi or Pump)

- Mechanic

- Needle

To facilitate your operations, our grippers are dismantled without tools, easy to use thanks to quick settings, an easy changeover and unlimited recipe.

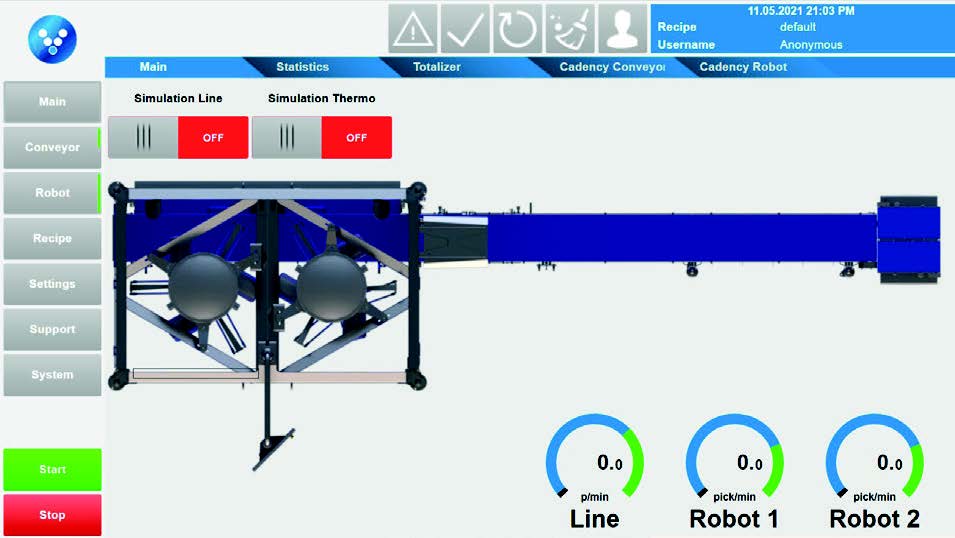

Boost The Efficiency Of Your Production Line With Our User-friendly HMI

To help you pilot, monitor and supervise your solution, we designed a simple HMI composed of a series of intuitive screens. Available in any language on simple demand, it provides you with data on your most recurrent default products.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).