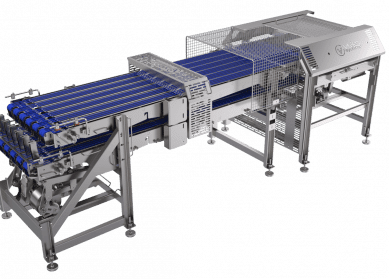

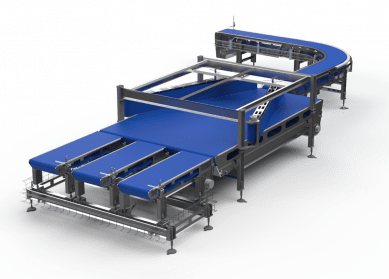

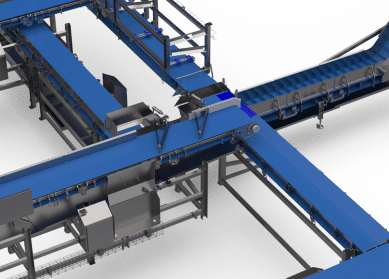

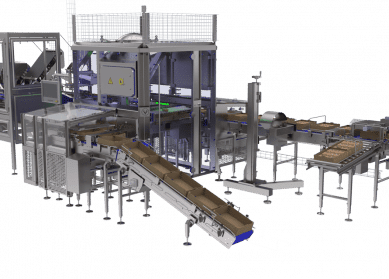

Because each cheese manufacturer has an existing plant, with its own constraints, and its own specific products, VELEC Systems designs the most flexible solution, easy to adapt and customized to each factory, each product and each production rate.

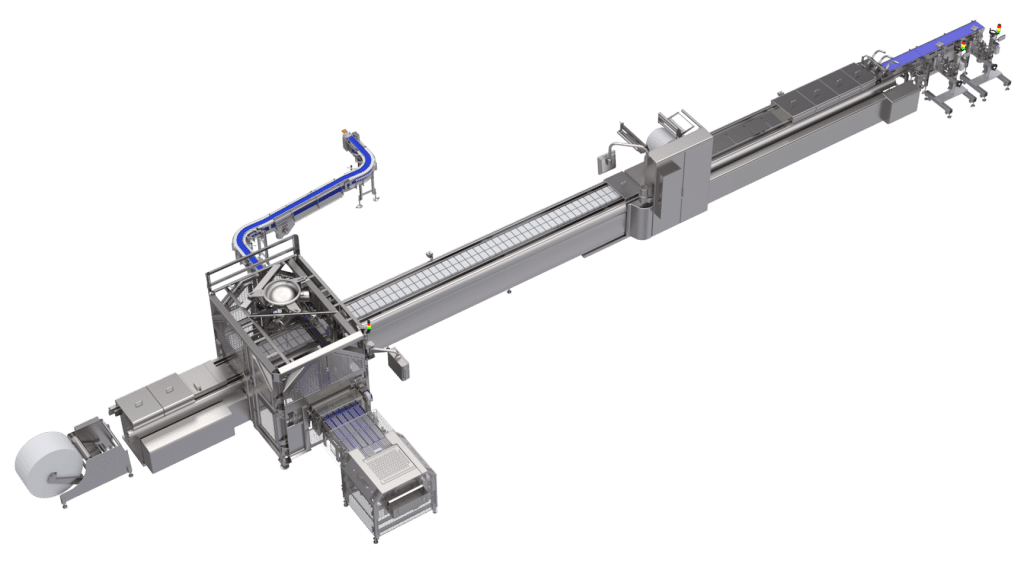

Our highly versatile cheese packaging line helps you optimize your production.

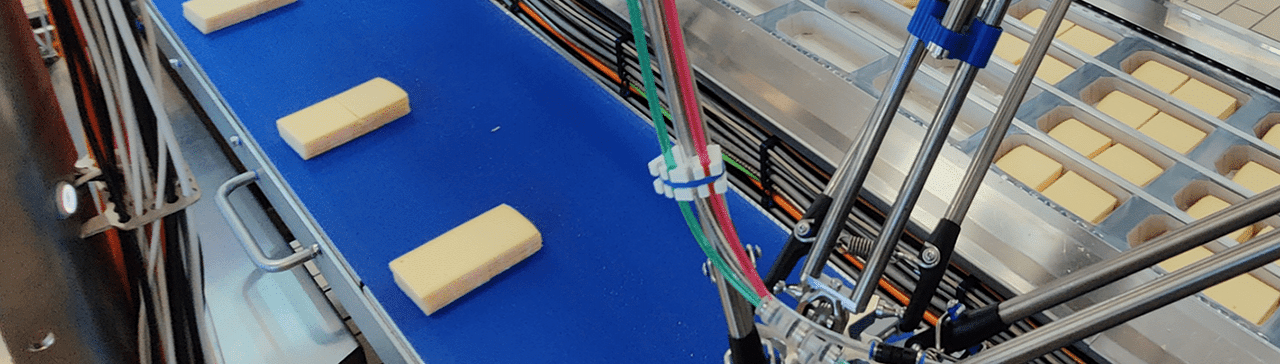

Located between your cheese slicer and your primary packaging solution, it is essential that this stage of your process is hygienically impeccable to prevent the development of bacteria before the packaging of your cheese into their primary packaging.

Thanks to our hygienic design equipments, we maximize the hygiene of your production rooms and increase your machine availability.

Highly flexible and versatile, it adapts to your production formats.

Optimize Your Production Thanks to Our Custom-made Solution

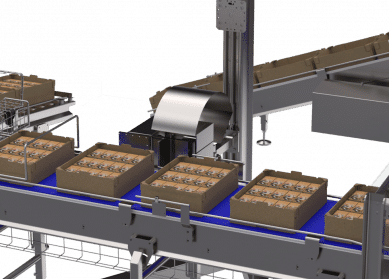

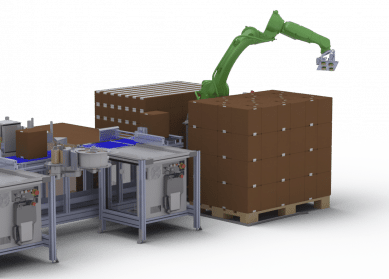

We support our customers by designing the complete cheese line adapted to their needs. By opting for our complete line, you will be able to produce your string cheese from the slicing to the palletization. You benefit from a turnkey service provided by our experts.

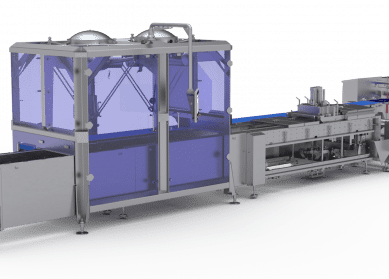

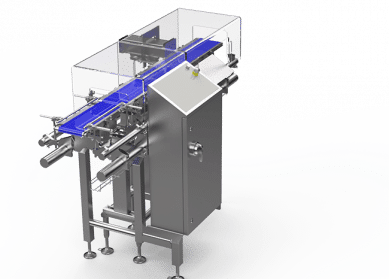

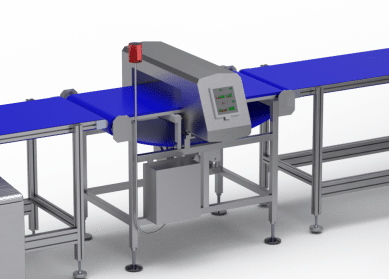

Maximize Your Process Thanks to State-of-the-art Equipment and a Quality Control System

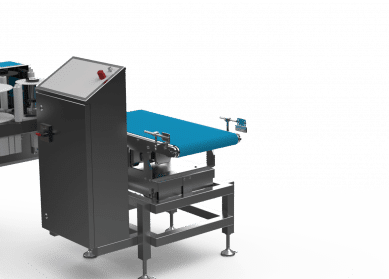

To optimize your production process our cheese loading line preserves the shape and texture of your products. Perfectly adapted, it causes no waste or damage.

In addition, a quality control system rejects non-conforming products based on their shape, diameter and length, to ensure perfect batches. To go further, our HMI system provides you with statistics on your most recurrent products’ defects, allowing you to adjust your quality plans.

Intuitive and Innovative Solutions for Your Productivity

To help you control, monitor and supervise your cheese loader, an easy-to-use HMI is available in all languages on request. Composed of intuitive screens and numerous control, maintenance and supervision functions, it is available in all languages on request.

Take Advantage of Remote Assistance to Maximize Your Machine Uptime

Interactive assistance is possible thanks to an integrated remote access via Ethernet, Wi-Fi or SIM card. The 360° camera control option allows you to establish a direct connection with our experts who will guide you in restoring your line, sparing you the expense of experts traveling to your production site.

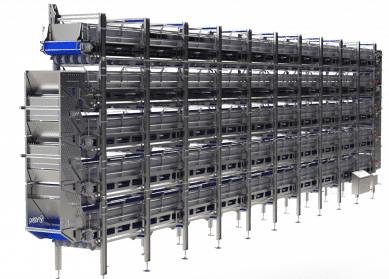

Increase Your OEE Thanks to the Highest Level of Hygiene in Your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).