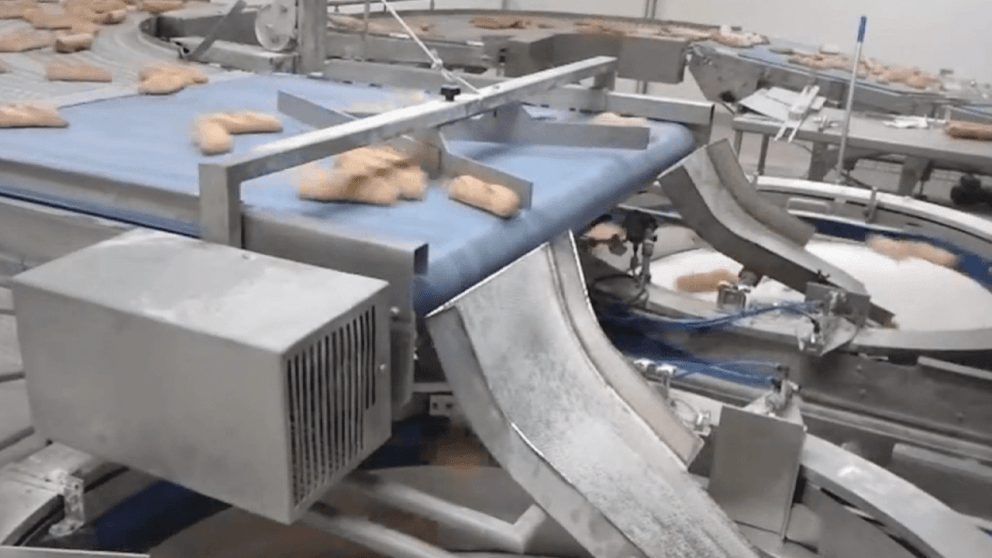

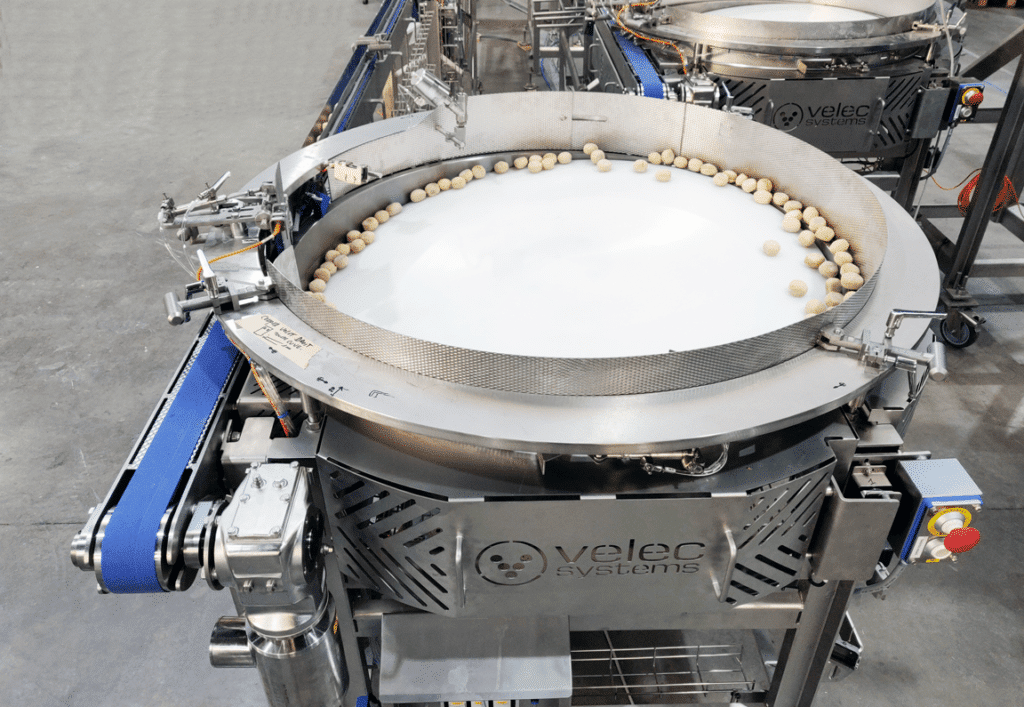

Our bread counting solution is designed and developed to align at high speed a bulk of breads into a continuous ordered flow.

It loads up to 33,000 products/hour

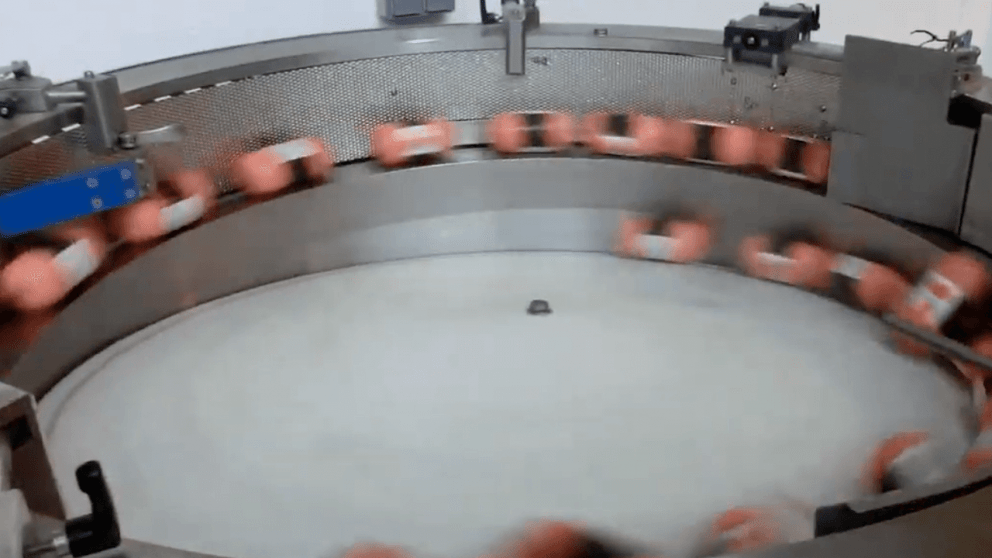

Our Centrifugal Machine Allows you to Maximize your Production by Counting your Products in Full Autonomy

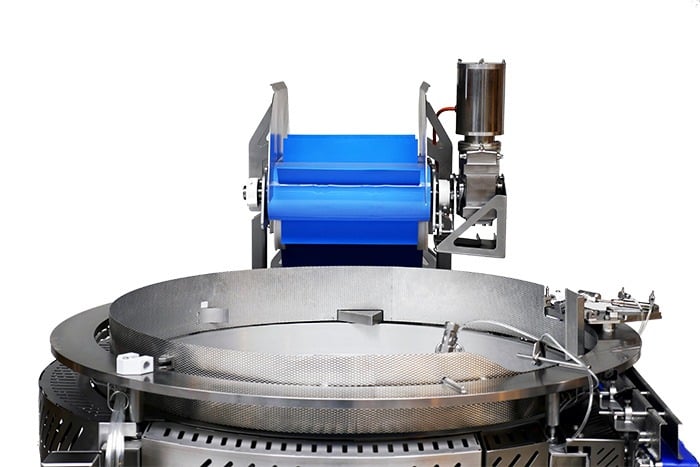

Thanks to the centrifugal force, the VELEC centrifugal machine brings your bread towards the edge of the tray without mechanical constraints. From there they are carefully counted and loaded thanks to predefined recipes. There is no loss of raw material or damage caused to your products.

Highly flexible, it adapts to your conditioning:

- Counting and bagging

- Counting and batching

Optimize your Cleaning and Maintenance Operations by Taking Advantage of its Small Footprint and Easy Access

Ergonomic, it can be installed in the narrowest spaces. Designed to be at ground level, it guarantees easy maintenance and cleaning. Safe and simple to use for your operators, it ensures the better efficiency of your operations.

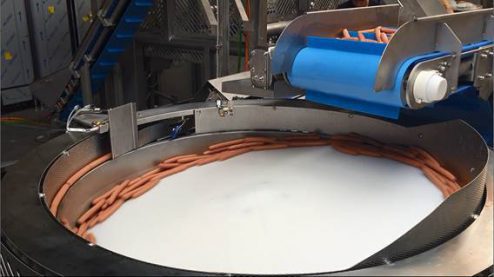

Increase your OEE Thanks to the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).