Identifying Common Challenges in Packaging Automation

Packaging automation can greatly improve efficiency and reduce costs for businesses. However, there are also challenges that companies may face when implementing automated packaging systems. Understanding these challenges and finding solutions is key to successfully automating your packaging process.

High Initial Costs

One of the biggest challenges of packaging automation is the high initial cost of purchasing and installing automated equipment. Machines like palletizers, vertical loaders, and thermoformers can be expensive, which can be a significant investment for any business.

Solution

To address this, businesses can look for financing options or leasing programs to spread out the cost over time. Additionally, it’s important to calculate the long-term savings that automation can bring, such as reduced labor costs and increased efficiency, which can offset the initial expense.

Training Employees

Introducing automated packaging equipment requires training employees to operate and maintain the new machines. This can be time-consuming and may initially slow down production.

Solution

Businesses can invest in comprehensive training programs for their employees. This can include hands-on training sessions, online courses, and detailed manuals. It’s also beneficial to have support from the equipment manufacturer to ensure that employees are well-prepared to handle the new systems.

Maintenance and Downtime

Automated packaging lines, like any machinery, require regular maintenance to keep them running smoothly. Unexpected breakdowns can lead to costly downtime and delays in production.

Solution

Implementing a preventative maintenance program can help minimize unexpected breakdowns. Regularly scheduled maintenance checks and keeping spare parts on hand can ensure that any issues are quickly addressed. Additionally, investing in high-quality, reliable equipment can reduce the likelihood of frequent breakdowns.

Integration with Existing Systems

Integrating new automated packaging equipment with existing systems can be a complex process. Ensuring that all machines work together seamlessly is crucial for maintaining a smooth production line.

Solution

Working with experienced system integrators can help ensure that new equipment is properly integrated with existing systems. It’s also important to thoroughly test the integrated system before full-scale implementation to identify and resolve any potential issues.

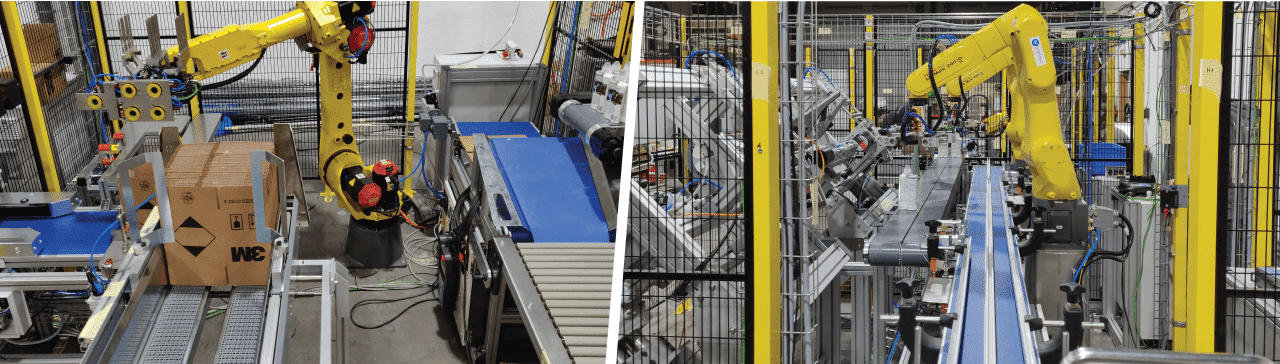

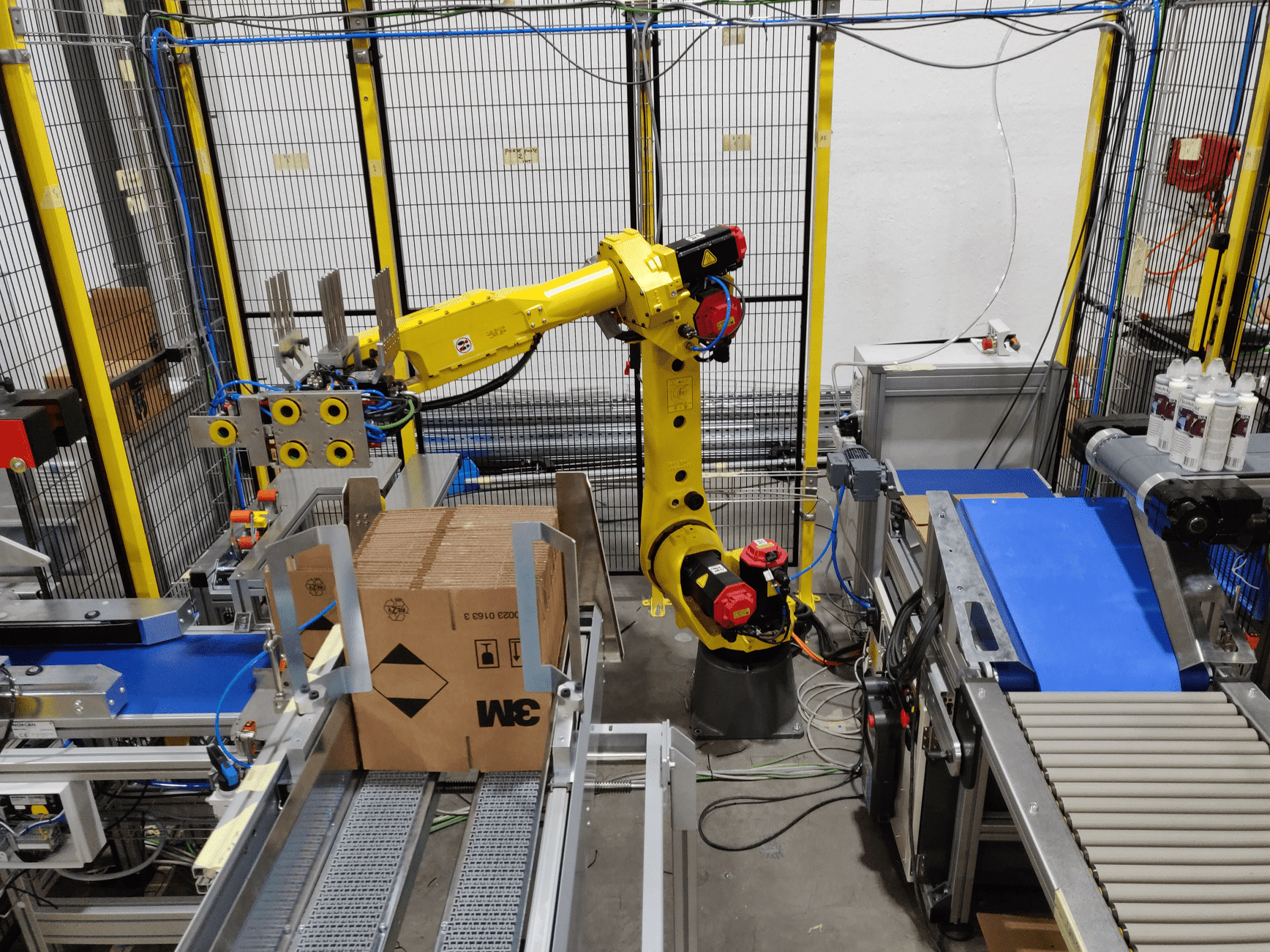

Adapting to Changing Product Lines

For businesses that regularly update or change their product lines, automated packaging systems need to be flexible enough to handle different products and packaging formats. This can be a challenge if the equipment is not designed for versatility.

Solution

Investing in modular and customizable automated packaging equipment can provide the flexibility needed to adapt to changing product lines. Machines like robotic palletizers and programmable vertical loaders can be easily adjusted to handle different products, reducing the need for frequent equipment changes.

Ensuring Product Quality

Automated systems must maintain high standards of product quality. Inconsistencies in packaging can lead to product damage and customer dissatisfaction.

Solution

Using advanced sensors and cameras in automated packaging lines can help ensure that each product is packaged correctly and meets quality standards. Machines like flow wrappers and thermoformers can be equipped with these technologies to detect and correct any packaging errors in real-time.

Space Constraints

For small businesses, finding enough space to install automated packaging equipment can be a challenge. Large machines like palletizers and vertical loaders require significant floor space.

Solution

Businesses can look for compact and space-saving equipment options. Some manufacturers offer smaller versions of their machines designed for tight spaces. Additionally, reorganizing the production floor to maximize available space can help accommodate new equipment.

Conclusion

While there are several challenges associated with packaging automation, there are also effective solutions to address them. By understanding these challenges and implementing the right strategies, businesses can successfully automate their packaging processes. This can lead to increased efficiency, cost savings, and improved product quality. Investing in packaging automation is a smart move for businesses looking to stay competitive and meet growing demand.

Is your business ready to use more automation? Contact Velec Systems today and learn how.